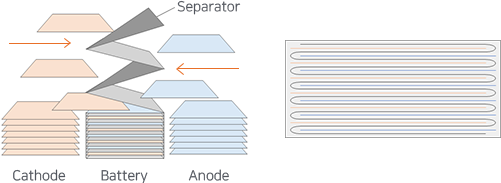

Z-folding Technology We have exclusive ownership of a stacking method that intersects and stacks cathodes and anodes between the separators in a zigzag shape to achieve the highest level of safety. The Z-folding technology minimizes cell stress and evenly stacks cathodes and anodes to prevent physical contact between electrodes, greatly reducing the potential risk of internal short and ignition of our batteries. In addition, the technology allows stable alignment between anodes and cathodes, and thus further improves safety. We have secured the highest level of aligned electrode manufacturing technology in the world in terms of high-speed stacking, which allows us to offer improved safety despite the acceleration of battery process production speed.